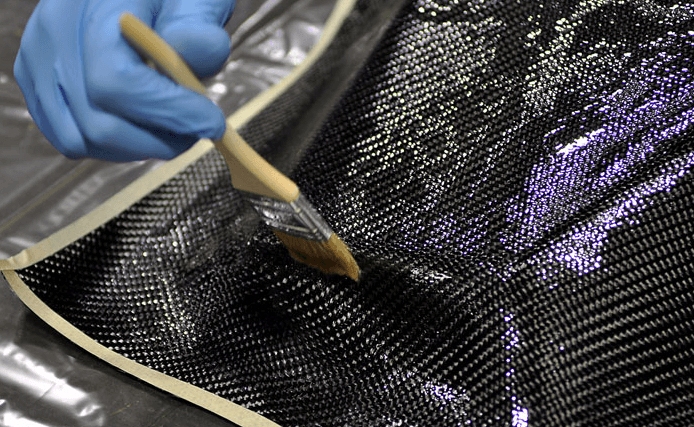

Resins

Our epoxy resins are premium, high-performance systems engineered for a wide range of demanding applications, including composite manufacturing, mold making, tooling, casting, and structural bonding. They deliver exceptional mechanical strength, superior adhesion, and excellent resistance to heat, moisture, and chemicals. Whether you're manufacturing lightweight structural parts, laminating reinforcements, or sealing and bonding tooling boards, our resin systems are formulated to meet the specific requirements of your process

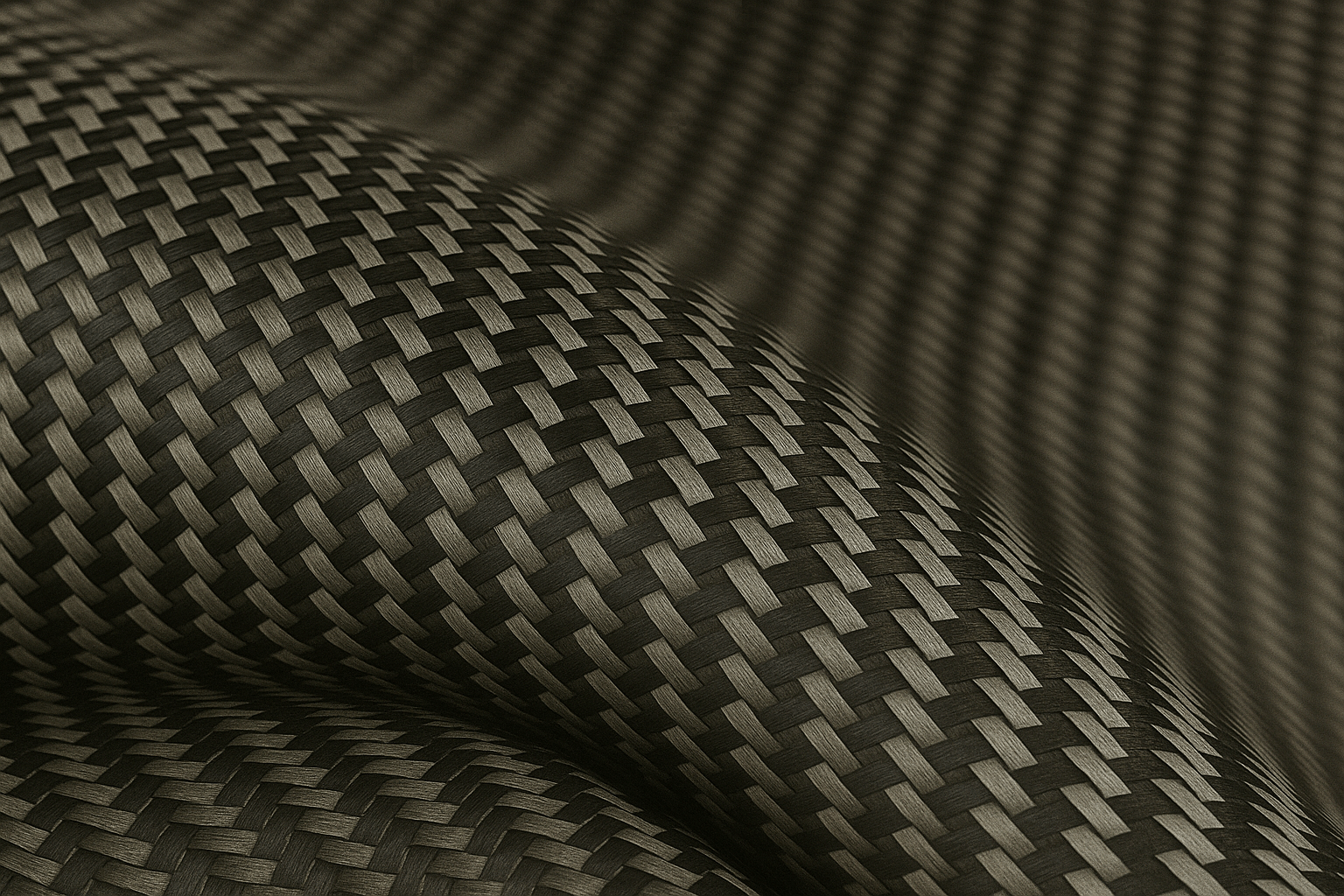

Fabrics

Discover our range of high-performance reinforcement fabrics engineered for demanding composite applications. We supply premium carbon, aramid, and carbon/aramid hybrid fabrics trusted by professionals in aerospace, automotive, marine, sports equipment, and industrial manufacturing. Our fabrics are selected for their exceptional mechanical properties, low weight, and durability, making them ideal for both structural and functional composite parts.

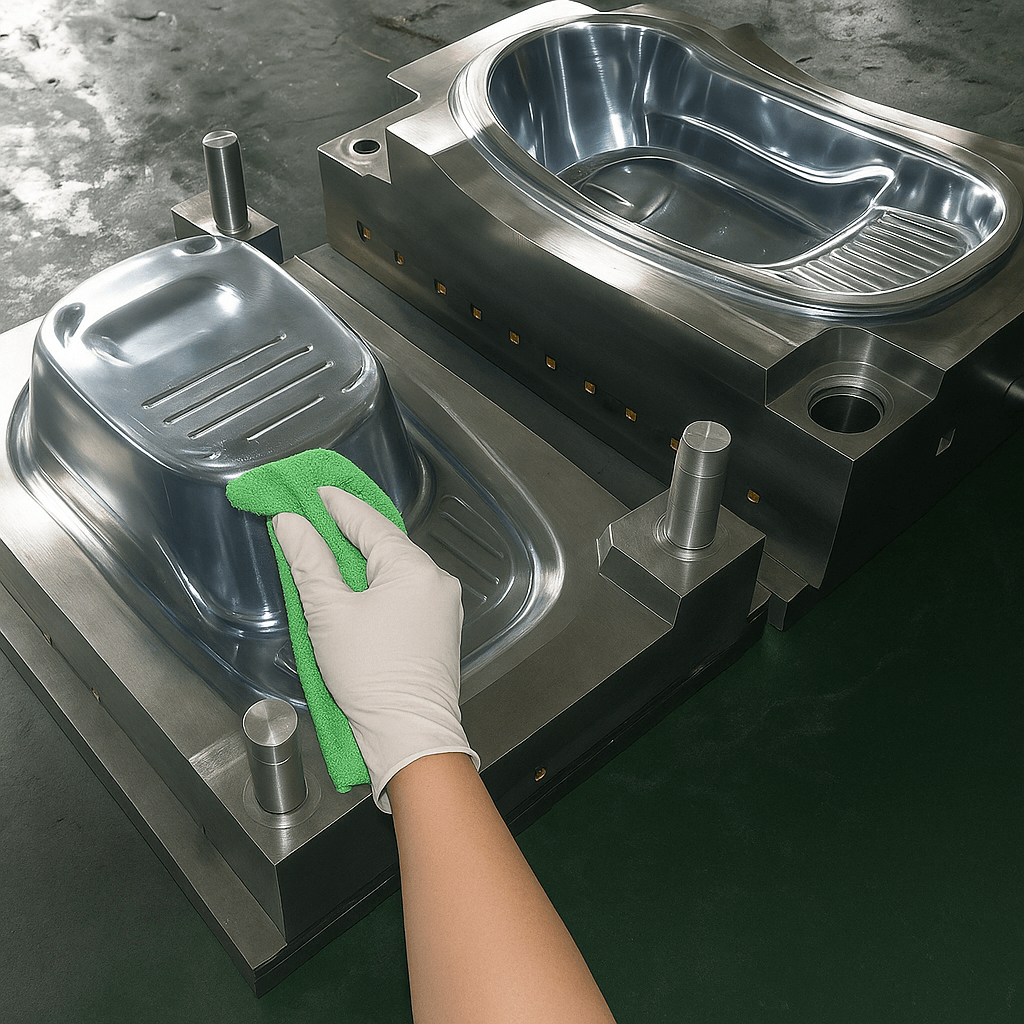

Tooling

Advanced tooling materials designed for high-precision mold construction, CNC machining, and composite manufacturing.We offer both polyurethane and epoxy tooling boards — lightweight, easily machinable, and available in a wide range of densities for modeling, prototyping, and high-temperature applications. Epoxy boards deliver excellent dimensional stability and heat resistance, making them ideal for thermoforming and composite tooling.Complementing the boards, our epoxy gelcoats provide a durable, high-performance surface layer with outstanding chemical resistance, low shrinkage, and thermal stability (up to 180°C). Ideal for RTM molds, prepreg tools, and protective coatings, they ensure long-lasting surface quality for demanding tooling environments.Whether you're producing a styling model, a high-temp mold, or a composite lay-up tool, our materials offer the strength, stability, and reliability your process demands.

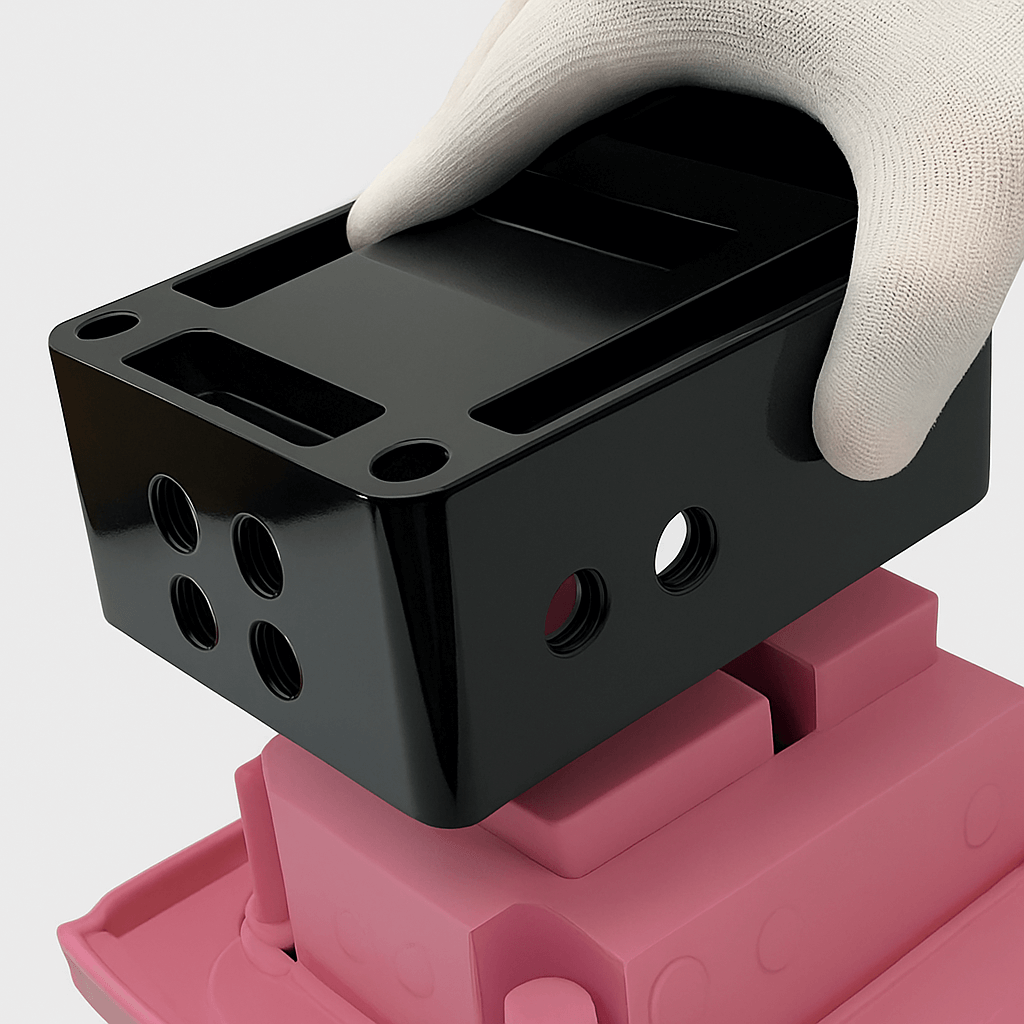

Silicones

Explore our selection of high-performance silicone rubbers for mold making in prototyping, casting, art, and industrial applications. We offer both addition-cure (polyaddition) and condensation-cure (polycondensation) systems to suit every molding need.Addition-cure silicones ensure fast curing and high precision for detailed or technical molds, while condensation-cure silicones offer excellent flexibility, longer working time, and cost-efficiency for general mold production.

Reliable, easy to use, and built for accuracy — our silicones help you achieve professional results with every cast.

Vacuum materials

We supply high-quality Diatex vacuum consumables designed for resin infusion, RTM, and other composite manufacturing processes. Trusted by professionals across industries, Diatex materials ensure reliable vacuum performance, consistent resin flow, and clean demolding results. Our range includes vacuum films, peel plies, flow media, breather fabrics, and release films — all engineered for efficiency and precision in advanced composite production.

Sealers and release agents

Our high-performance sealers and release agents are developed for use in composite molding, prepreg lay-up, and high-temperature tooling. They help seal porous mold surfaces, enhance gloss, and ensure clean, consistent demolding across multiple cycles — without build-up or transfer. Perfect for use with epoxy, polyester, vinylester, and carbon fiber systems in both room temperature and elevated temperature processes.

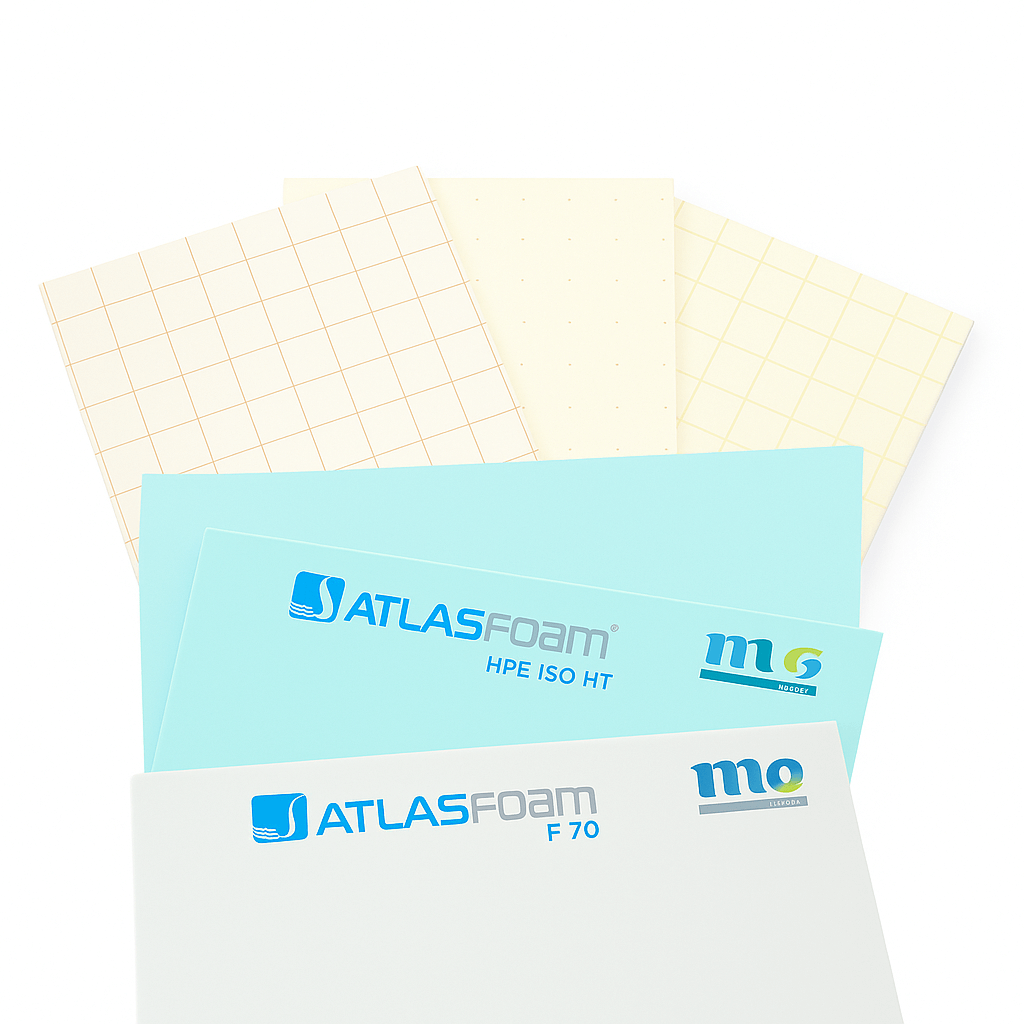

Core materials

We supply advanced core materials designed to meet the performance, processing, and sustainability needs of the composites industry. Our main offering, Atlas HPE, is a high-performance structural foam engineered for modern sandwich constructions, ensuring lightweight, strength, and durability across demanding industrial applications. Whether you're producing marine parts, automotive panels, wind turbine blades, or lightweight structures for architecture and transport, our closed-cell rigid foams — such as Atlas HPE, Atlas HT, and Atlas F