Plasters for Foundry and Mold Casting Applications

Our industrial-grade plasters are specifically engineered for demanding foundry and mold-making applications, delivering precision, durability, and thermal resistance across a variety of industries.

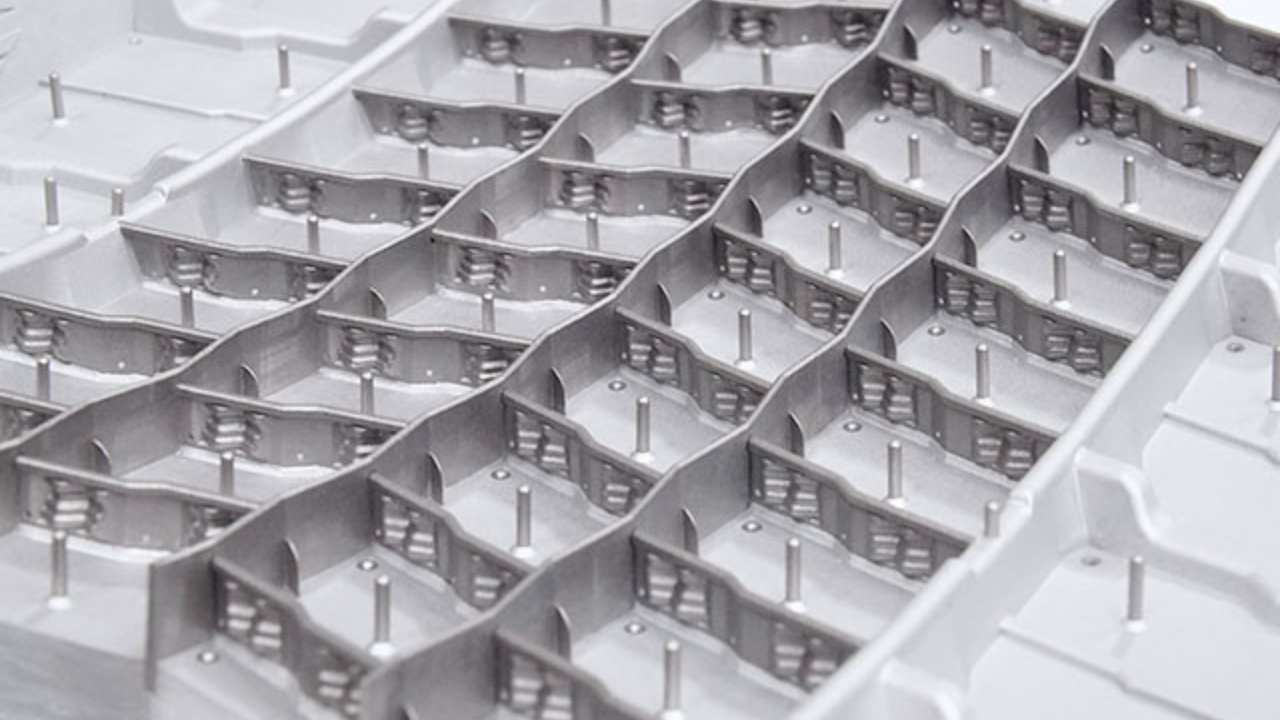

Used extensively in gold casting, tyre mold production, and general foundry operations, these plasters ensure sharp detail replication, excellent surface finish, and dimensional stability throughout the casting process.

Key Applications:

- Jewelry and precious metal casting

- Aluminum mold manufacturing for tyres, cosmetics, and plastics

- Industrial prototyping and foundry modeling

- High-temperature investment casting

Performance Characteristics:

- Exceptional mechanical strength and heat resistance

- High stability against metal corrosion

- Excellent thermal isolation, minimizing cracking risk

- Capable of withstanding casting temperatures up to 700°C

- Controlled setting time and expansion for consistent results

Technical Highlights:

- Water/Powder Ratio: 30–35%

- Setting Time: ~9 minutes

- Thermal Expansion (400–480°C): ~1%

- Ready for casting after proper drying and thermal cycling

Ideal for:

- Small foundries

- Mold and die shops

- Jewelry makers

- R&D and prototyping facilities

- Educational and technical institutions

Compatible with release agents and spray coatings to facilitate demolding and minimize surface defects.

Supplied in 25 kg paper bags

Shelf life: 36 months when stored dry in original packaging